KNITTING

KNITTING

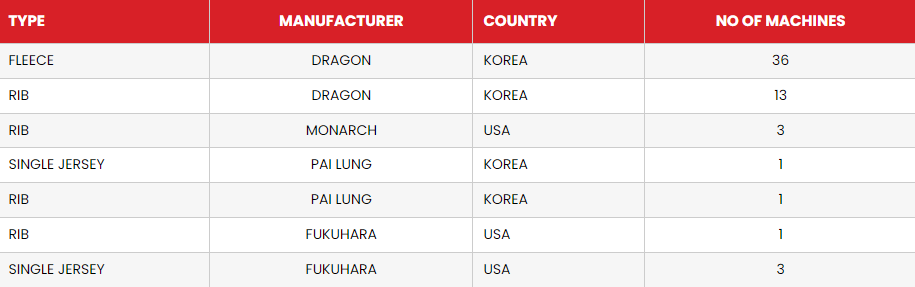

In Layallpur Knitwear knitting division, we have 60 state-of-the-art, diversified, and modern knitting machinery, produced by world-renowned knitting machine manufacturers that enable us to produce top-quality knitted fabric meeting the requirements of our valued customers.

We have variety of knitting machines from basic single jersey to complex double-knit jacquard structured machines.

Fleece

Our fleece machines are manufactured by top Korean knitting machine brand for different sizes and types of fleece like Cross Fleece and Plain Fleece having per day capacity of 10 tons kg per day.

Double Knit

All variety of double knit fabrics are available in-house including. We can produce 5 tons of simple rib, variegated rib, interlock, double layer interlock, mini jacquard and fully jacquard every day.

Single Jersey

Our single jersey machines are capable of knitting 5 tons of pique, honey comb pique and single jersey spandex other than single jersey with top quality.

Machinery Details and Capacity

CUTTING

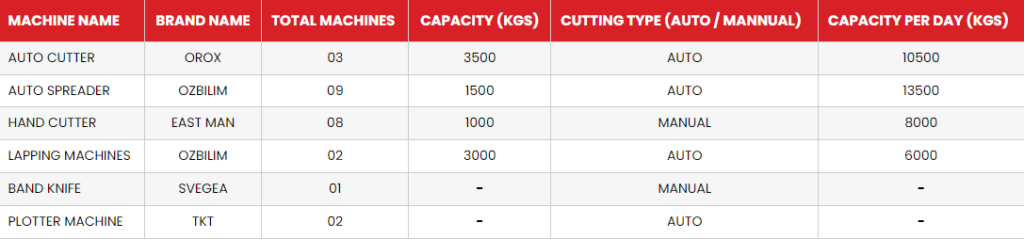

The cutting department is equipped with state-of-the-art auto-cutting machines having the capacity to cut 25,000-30,000 pcs per day, while the manual-cutting output is 10,000-13,000 pcs per day, sufficient enough to fulfill the required need of stitching units.

Machinery Details and Capacity

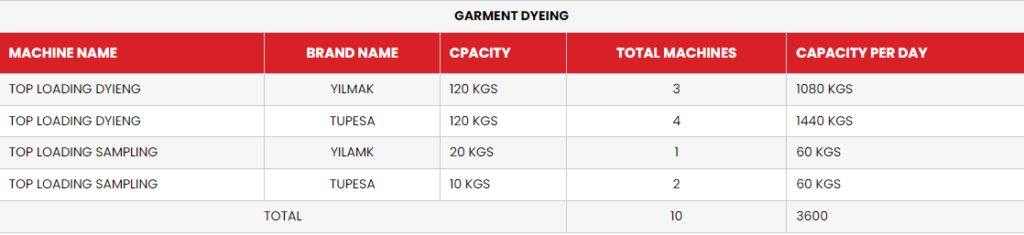

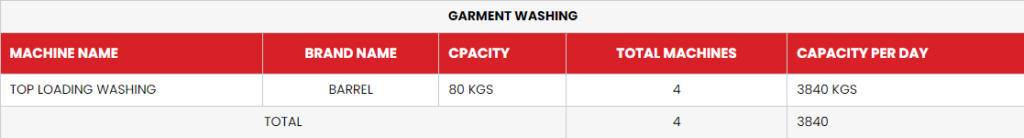

LAUNDRY

Machinery Details and Capacity

STICTHING

With more than 2300 stitching machines, manned with the most skilled and expert operators, Lyallpur Knitwear is capable of producing more than 53,000 pcs per day versatile garments ranging from basic to high fashion, men’s, women’s, and kids with maximum flexibility in size and color assortments.

All stiof teaching units are equipped with high-speed precision stitching machines operated by skilled labor experienced in shaping fabrics into different product sizes and styles as per the requirements of buyers from various countries.

The Quality control and Quality Assurance departments are in place to make sure the company’s objective of zero rejection

All orders are inspected and tested by SIRI LANKAN QA TEAM to ensure compliance with customer specifications. They are then packed for final shipment to their destinations all over the world.

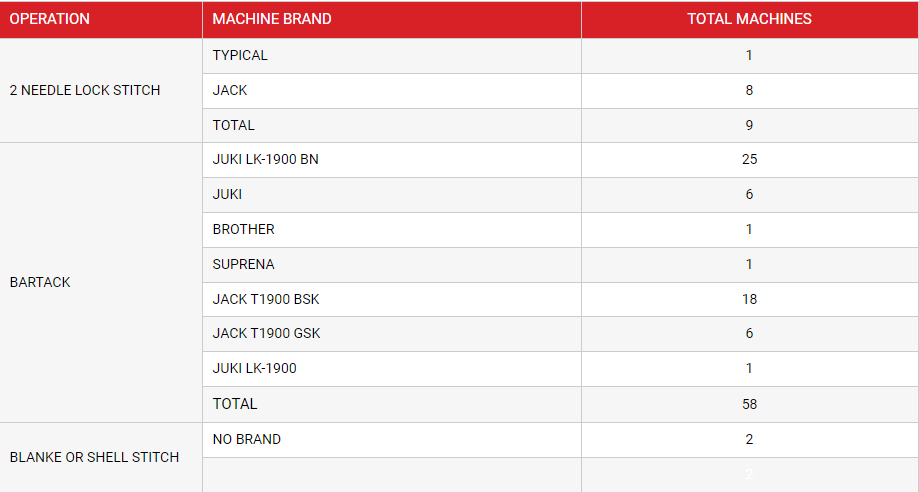

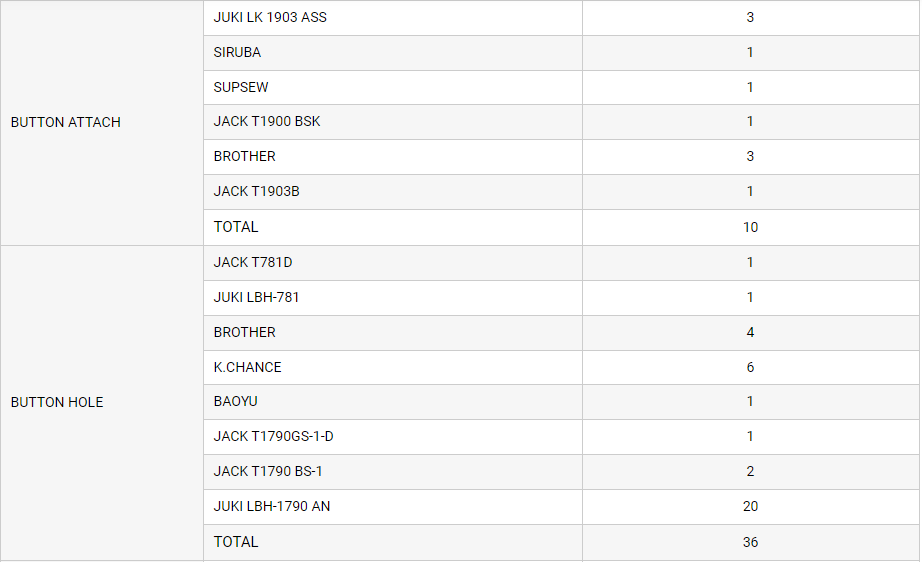

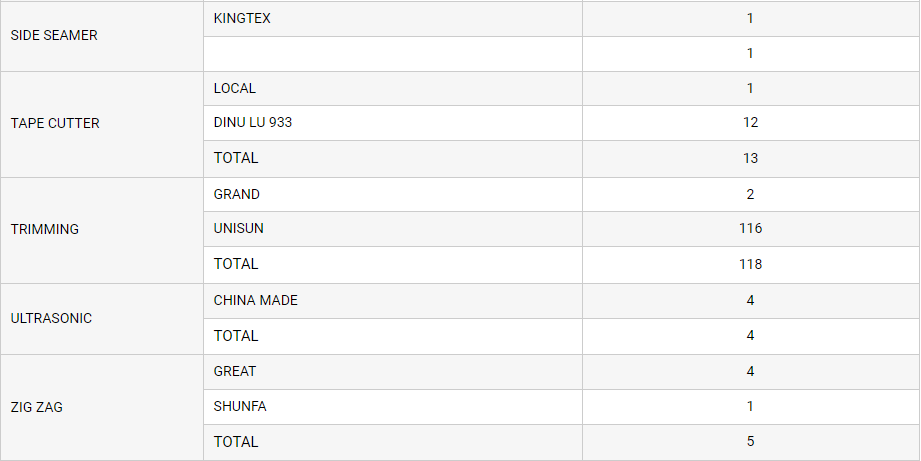

Machinery Details and Capacity